AI for visual Quality Control

36ZERO VISION brings the power of AI and computer vision to the fingertips of any manufacturer. We believe in smart manufacturing through a technology-driven approach that improves quality control with fewer resources – making it accessible to any manufacturer.

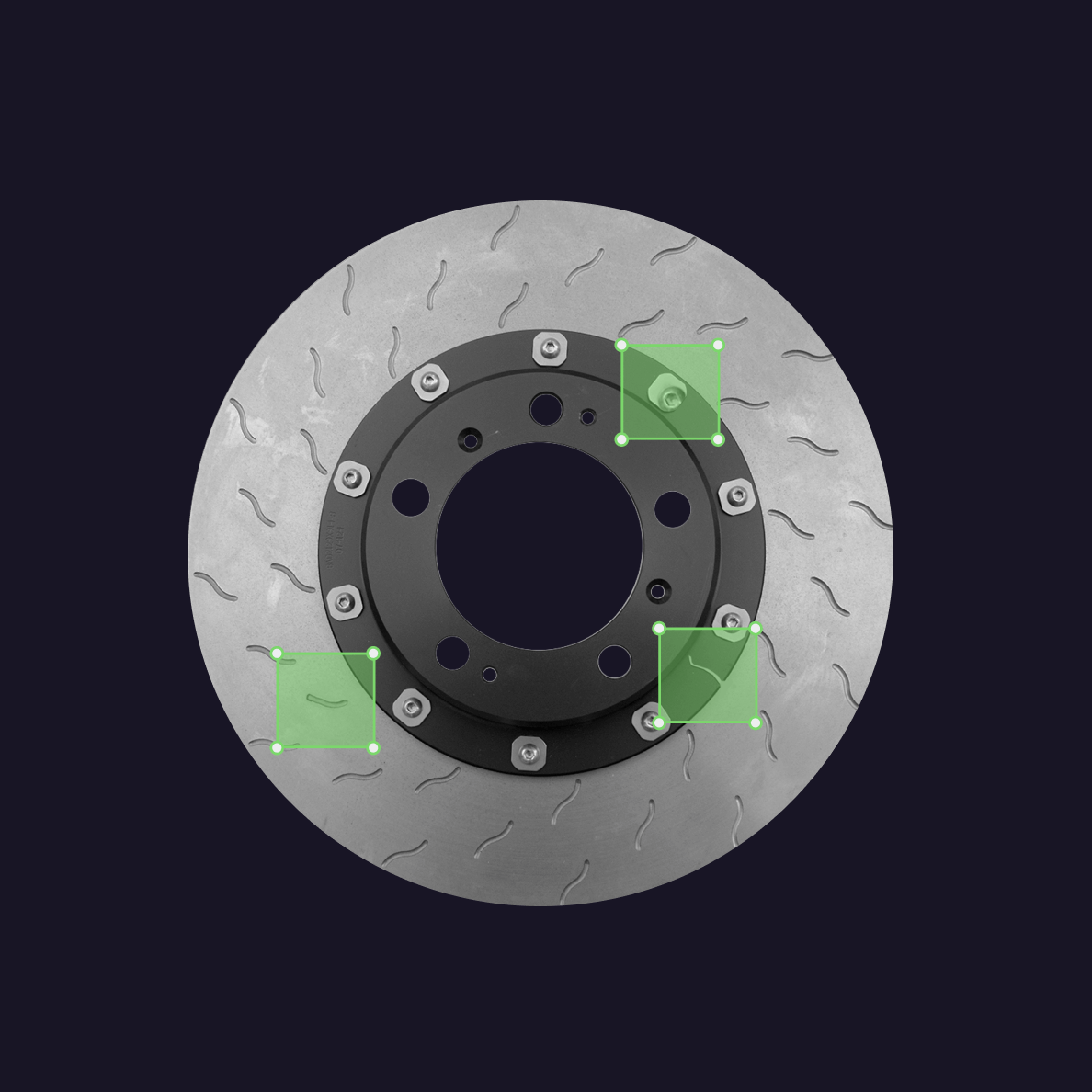

Mark the 3 defects

with your cursor

You have successfully trained

the AI to find the defects

Deep learning based error pattern recognition

No-code

self-service platform

The hardware-agnostic solution can be implemented in both new and existing setups across industries and product types.

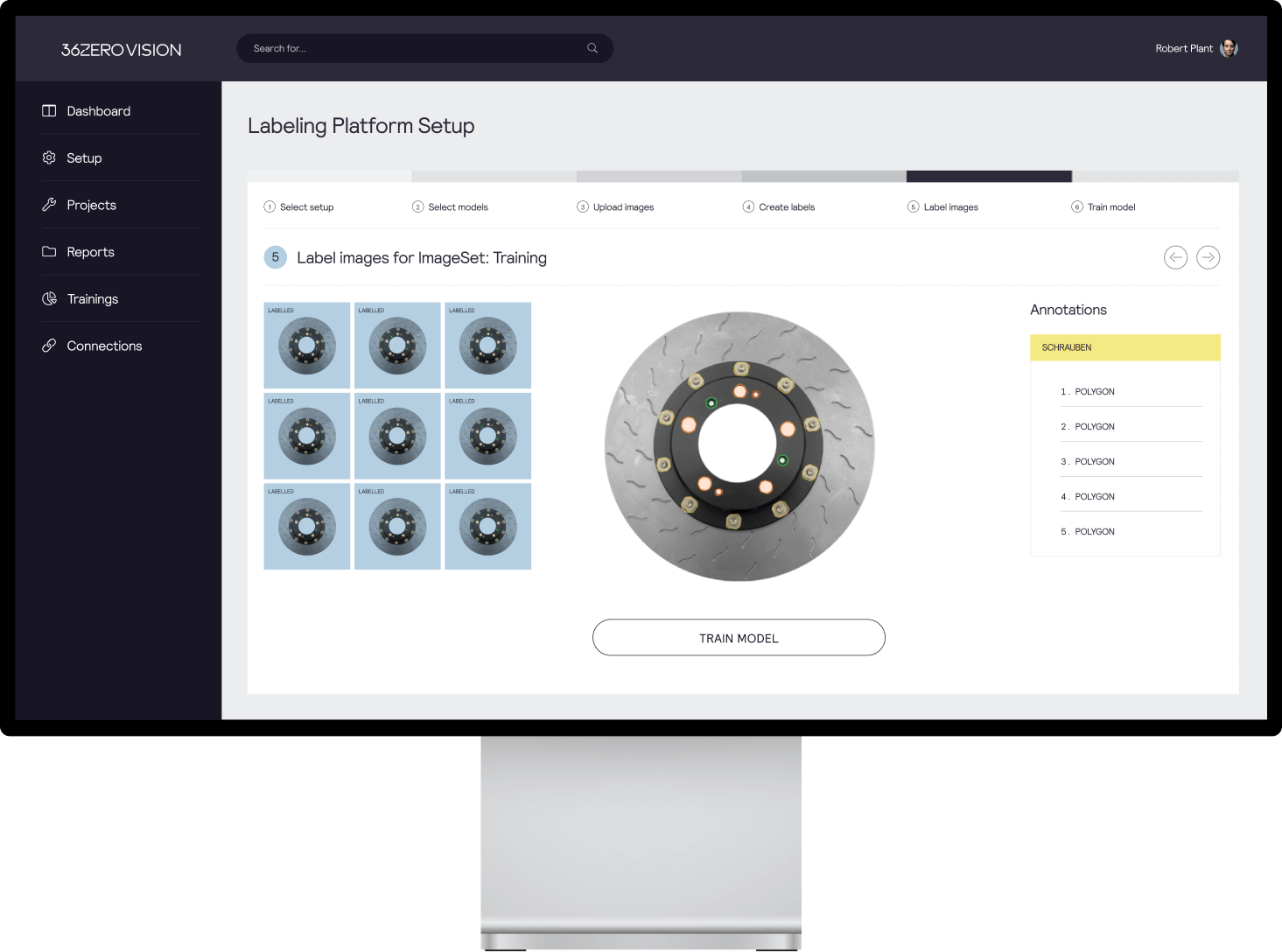

The software setup is easy and intuitive. Neither expert nor programming skills are required to set up individual quality inspection applications.

01

Upload Images

You can use the 36ZERO Vision web platform from any workstation or laptop to securely upload images and train the algorithm.

The algorithm can then be used on-edge on your industry PC or hardware that we provide. Easy to integrate and quick to set up with existing or new camera hardware.

- Setup of the algorithm from any workstation

- Upload 20x less images from the production line

- CAD files can be used for setting up the algorithm to reduce image taking time in production

02

Fault inspection

All functions on the platforms are easy to use and can be set up in a matter of clicks. There is no coding knowledge required.

The user selects the appropriate model, labels the characteristics, anomalies or missing parts, and trains the algorithm.

- Customer can setup the algorithm without coding knowledge

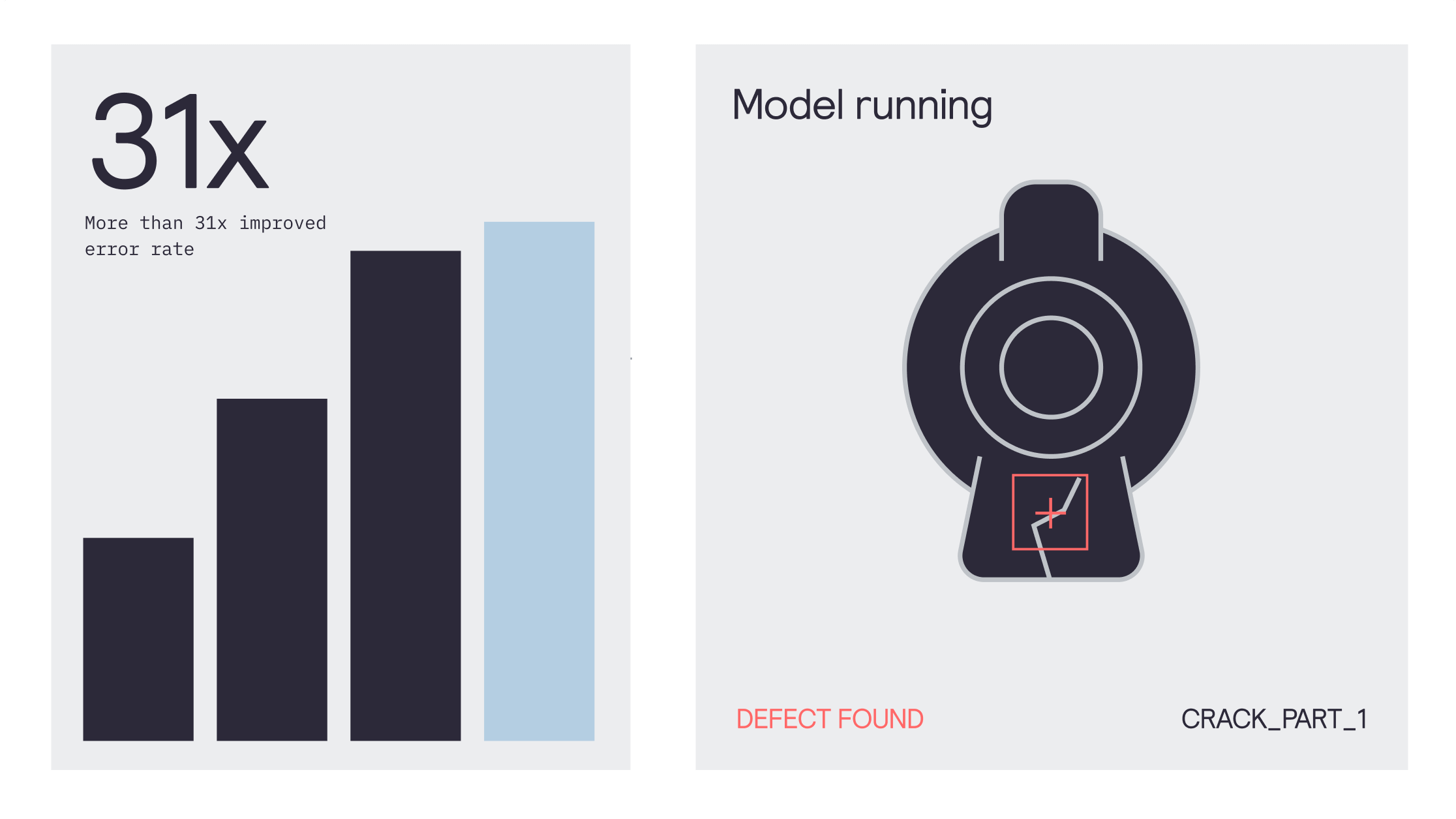

- 31x improvement identifying known faults. The robust algorithm learns the pattern of the defects and finds known characteristics

- 2x improvement identifying anomalies. The algorithm finds all anomalies including unknown defects. A stable environment is needed

03

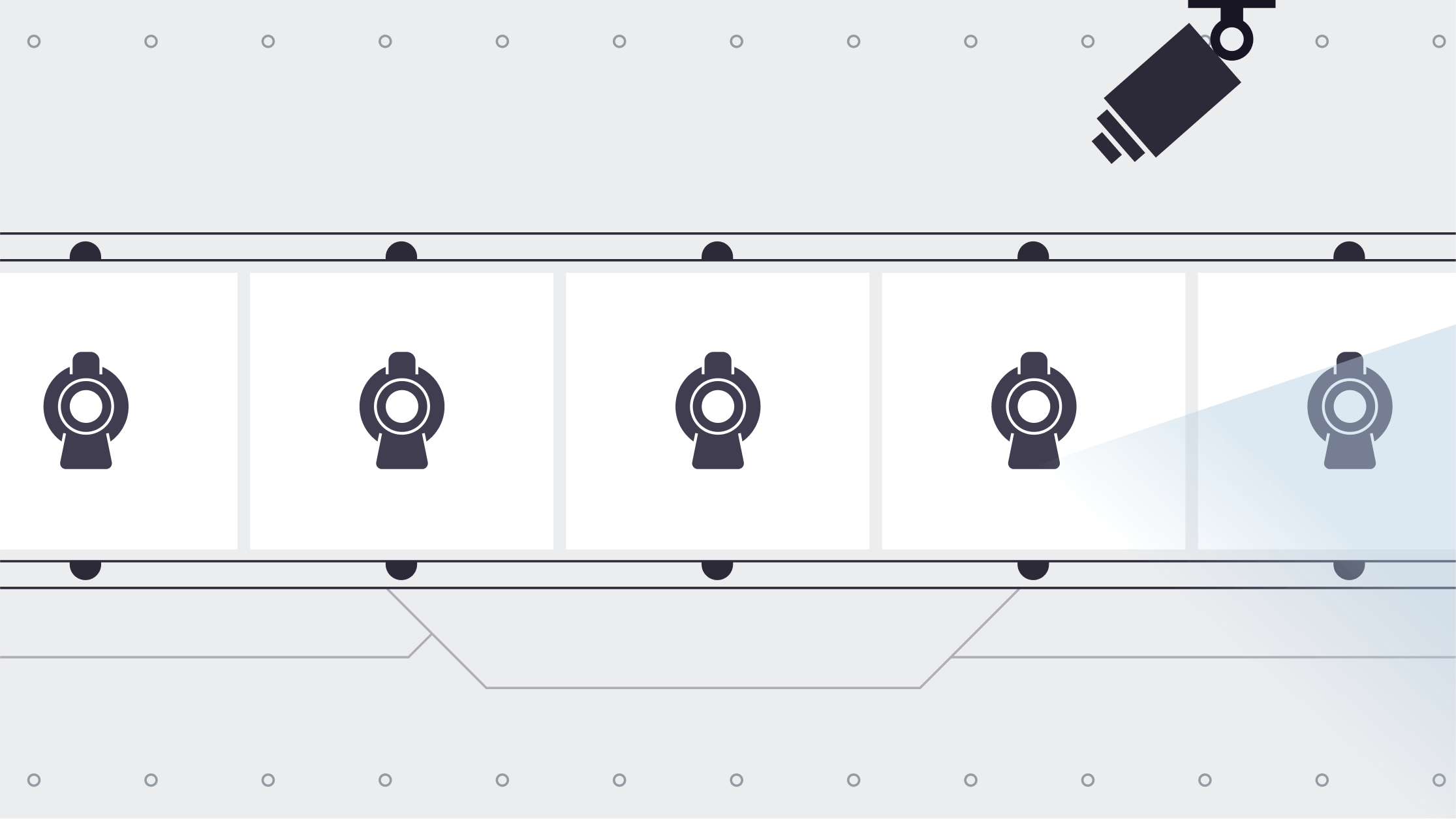

Run your production with the best automated quality control

The AI is highly capable and works with all kinds of parts and industries. It identifies defects, anomalies, missing parts as well as industrial text on a pixel level.

Furthermore, the AI is robust and flexible at the same time.

- Use of the algorithm on your industry computer in a matter of a click

- Continuous improvement of the vision AI through human feedback

- Easy integration into existing production systems

Vision without intelligence

is wishful thinking

36ZERO Vision is a vision solution for all kinds of assembly lines, be that fully automated or manual. It enables a serial production with automated quality inspection to radically improve quality and productivity, and reduce risk of recalls and worker dependency.

We offer powerful yet simple software that delivers everything you need to manage your quality control needs.

15k

images per minute

3bn

executed inspections

0

AI experience required