No defect ever

leaving the

factory again

Cutting-edge technology and agility of usage meet to improve and automate quality control and ensure production reliability independently, quickly, and without any coding knowledge

Easy &

scalable

Fewer images &

No-code

Hardware

agnostic

Robust

algorithm

Less

Hardware

Retrofitting

Benefits

Impact that’s felt from the first day of implementation

36ZERO Vision enables manufacturers to radically improve quality control from day one.

Artificial

intelligence

for tangible results

Powered by artificial intelligence and deep learning, our solution offers unparalleled efficiency and consistency.

36ZERO Vision’s algorithm can be trained with just a few pictures, drastically reducing the number of errors leaving your factory.

With image analysis on a pixel level, our technology can be customized for any use-case, ensuring that you achieve unprecedented levels of quality control.

Less trouble

for less errors

Software beats hardware any day

of the week.

We’re obsessed with user-needs and making the latest technology, computer vision and AI, accessible to our customers.

With our solution, you’ll gain an almost unfair advantage by achieving better results with fewer resources.

Our platform enables anyone in your team to perform quality inspection at the highest level, saving time and increasing value for your customers

Consistency in

ever-changing

environments

Say goodbye to hardware-based solutions and hello to agile quality control with our software-based technology.

Our intuitive and code-less training platform, combined with AI learns quickly and adapts to changing factory conditions.

36ZERO Vision allows any factory to achieve unprecedented accuracy with a smaller hardware investment, even working with technology as simple as smartphones.

Agile. Intelligent.

Measurably superior.

Our AI software solution delivers better results with fewer resources. It can be set up in just a few clicks and enables all employees in your company to carry out visual quality controls at the highest level.

Do you still see

or already have

a vision?

01

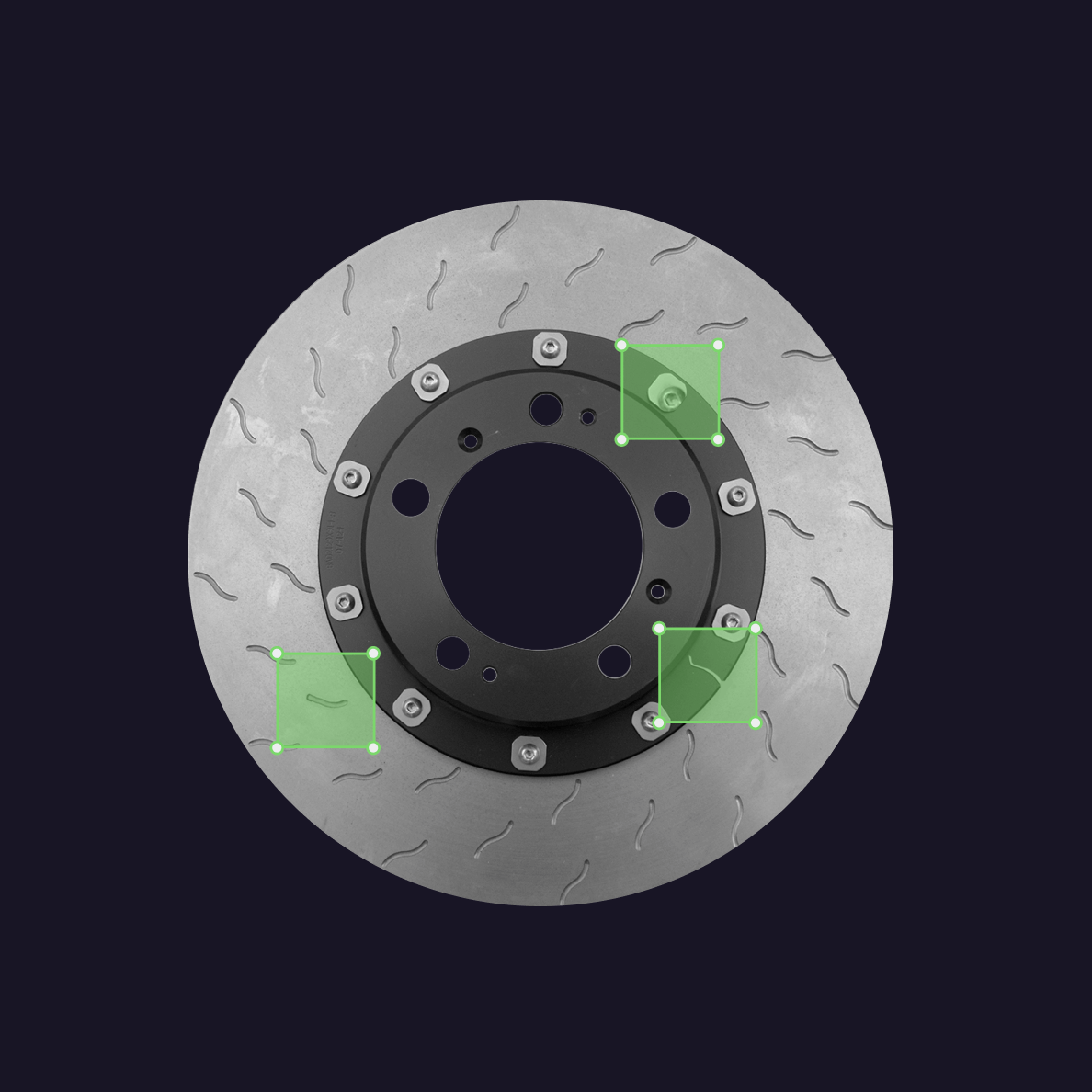

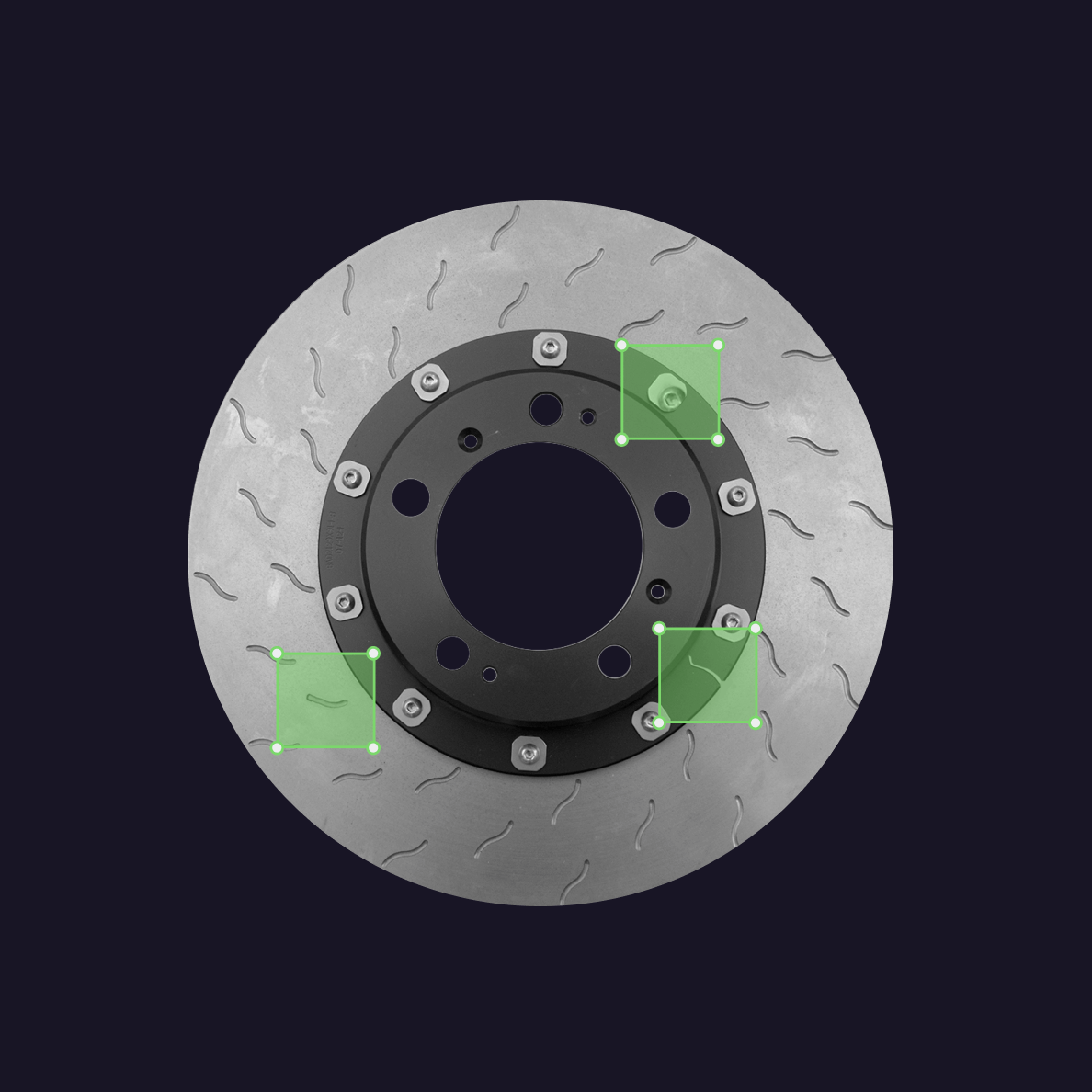

Intelligent visual inspection

This module ensures traceability and transparency throughout the manufacturing plant. It allows access to the images of all produced parts sorted by plant, date, and time.

HOW IT WORKS?

- Smart detection with AI of the relevant part

- Automated image acquisition without additional hardware

- Metadata gets added (e.g. reading of text, adding of time, product type, production line)

02

Fault inspection

This module helps us to carry out multiple inspections with one camera, take into account different requirements for the different areas or components and ensures a flexible, fast and smooth inspection.

HOW IT WORKS?

- Detection of the relevant part

- Multiple parts can be detected with one camera

- Each part can be inspected with the same or different algorithms

03

Execution of the algorithm

This module enables the detection of visual imperfections on surfaces such as scratches, dents, cracks, color irregularities or blowholes. It checks the component for anomalies or the assembly for missing parts and incorrect configurations.

HOW IT WORKS?

- The algorithm is used for the relevant part

- Output: OK/ NOK of the fault type, anomalies or missing part

- Real-time notification to all relevant interfaces

Radical optimization for the

best possible quality

With constantly changing requirements and increasing complexity, manufacturers must act and implement automated solutions to remain competitive. 36ZERO Vision reduces the costs of recalls, rework, and labor costs with fewer resources. At the same time, we improve the quality and reliability of production through easily accessible quality control. Our solutions are continuously developed and expanded with efficient functions.

Retroactive inspection

With 36ZERO Vision it is possible to examine all recorded images retrospectively. This significantly reduces the risk of errors and the costs of processing recalls.

Continuous Improvement

36ZERO Vision enables continuous improvement of the algorithms. Through the cooperation of employees and our AI, we achieve the best possible results for conducting an objective inspection, especially in borderline cases.

CAD Setup (Beta)

In addition to production images from the installed cameras, CAD files can also be used to teach the algorithms. This significantly reduces the time it takes to take pictures, the effort required to mark errors and the downtime required to set up the line.

Adding metadata

Product-related data such as serial number or product model can be read out automatically.

This information is then automatically added as metadata to each image, enabling traceability throughout the production process.

GDPR Compliance

Ensure data protection: Faces and other body parts are blurred before saving. This means that 36ZERO Vision can also be used without security zones in areas with employees.This information is then automatically added as metadata to each image, enabling traceability throughout the production process.and stored.

Integration with other systems

Integrate 36ZERO Vision in no-time thanks to advanced quality management systems. For example, our integration process enables defective parts to be sorted out by a robot.

Experience a new era

of quality inspection

in an era of ever-changing demands and increasing complexities, where manual quality control is prone to errors, where automated solutions are often rigid, hardware-based and slow to adapt or implement – 36ZERO Vision is the agile and cost-efficient solution.